Discover how you can purge chemical plant equipment containing hydrocarbon residues or volatile organics with IN2ERT™

Tailored specifically to the needs of base and petrochemical producers, our turnkey industrial service portfolio gives you a quick, cost-effective way to safely and accurately meet your plant and pipeline service needs. We cover the full service spectrum from testing, pigging and drying of existing and new pipelines - including those in challenging, off-road locations - to turnkey management of plant turnarounds and MRO (maintenance, repair and overhaul) work.

We provide solutions tailored to your unique operational and environmental requirements. For every job, our team brings a consultative approach with a wealth of experience, focusing on safe and efficient project execution.

At Linde, we understand that chemical plants have very specific and exacting requirements when it comes to industrial gases. Pressure, temperature, purity and volume requirements can vary significantly across a range of highly specialized applications. We deliver the gases nitrogen, oxygen, argon, methane, carbon dioxide and carbon monoxide in a variety of supply modes, flow rates, pressures and temperatures.

Discover how you can purge chemical plant equipment containing hydrocarbon residues or volatile organics with IN2ERT™

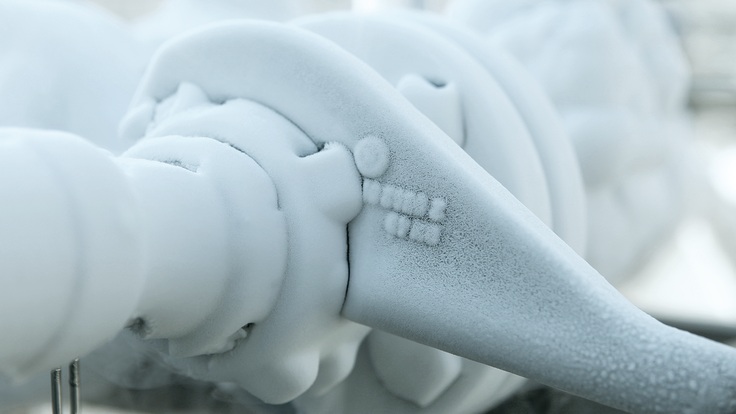

Improve safety and efficiency in chemical production environments with inert gases for drying, inerting, blanketing and purging

For when your normal supply of industrial gases doesn’t meet the flow, pressure or temperature of your temporary requirements

Get ahead of leaks before they impact your bottom line with our solutions for pipeline and tank leak detection

Accelerate and simplify maintenance and inspection work in chemical plants with our nitrogen-enabled pipeline pigging services

Accelerate your reactor turnaround projects with our comprehensive service portfolio spanning inerting, LEL freeing and accelerated cooling